plastic stabilizers

Links

- Methyl hydroxyethyl cellulose (MHEC) is a versatile polymer that is commonly used in various industries such as construction, pharmaceuticals, food, and cosmetics. As the demand for MHEC continues to rise, manufacturers play a crucial role in ensuring the availability and quality of this important material.

- One of the key characteristics of HPMC is its ability to form films and coatings. This property makes it an ideal ingredient in pharmaceuticals, where it is used as a coating for tablets and capsules to improve stability and appearance. HPMC is also used in the food industry as a thickener, emulsifier, and stabilizer in products such as sauces, beverages, and ice cream.

-

The Price Dynamics of Hydroxypropyl Methylcellulose Trends and Influencing Factors

-

Understanding Hydroxyethyl Cellulose

-

Moreover, increased focus on sustainability is shaping the market. Manufacturers are increasingly looking for eco-friendly ways to produce hydroxyethylcellulose, which may lead to shifts in pricing structures as investments in sustainable production techniques rise.

-

The properties of cellulose ethers are varied and depend on the specific type of ether, the degree of substitution, and the molecular weight. Common types include methyl cellulose (MC), ethyl cellulose (EC), hydroxypropyl cellulose (HPC), and hydroxypropyl methylcellulose (HPMC). These ethers are typically white, odorless powders that are soluble in water or organic solvents, depending on their substituent groups.

-

HPMC and MC both have their own advantages and disadvantages, and we can compare them to choose according to our needs and preferences:

-

Conclusion

-

In conclusion, liquid thickeners are indispensable in the food and beverage industry, enhancing texture, stability, and overall product quality. Their ability to accommodate specific dietary needs further underscores their importance in today’s diverse market. As consumer preferences continue to evolve, the demand for innovative and effective liquid thickeners will undoubtedly grow, pushing the industry toward continuous improvement and experimentation. Understanding the nuances of these ingredients will empower food manufacturers to create products that not only satisfy but also delight their consumers.

-

Conclusion

-

Benefits of HPMC

-

4. Personal Care Products In cosmetics and personal care, HPMC is incorporated into lotions and creams for its thickening and emulsifying properties. The viscosity level impacts the sensory experience of the product, making it crucial for consumer acceptance.

-

HPMC is synthesized through the reaction of cellulose with propylene oxide and methyl chloride. The numbers in its name, such as 4000, indicate the viscosity grade—specifically, the viscosity of a 2% aqueous solution at 20°C, which for HPMC 4000 is approximately 4000 mPa·s. This viscosity allows HPMC 4000 to function effectively as a thickener, gelling agent, and suspension agent.

-

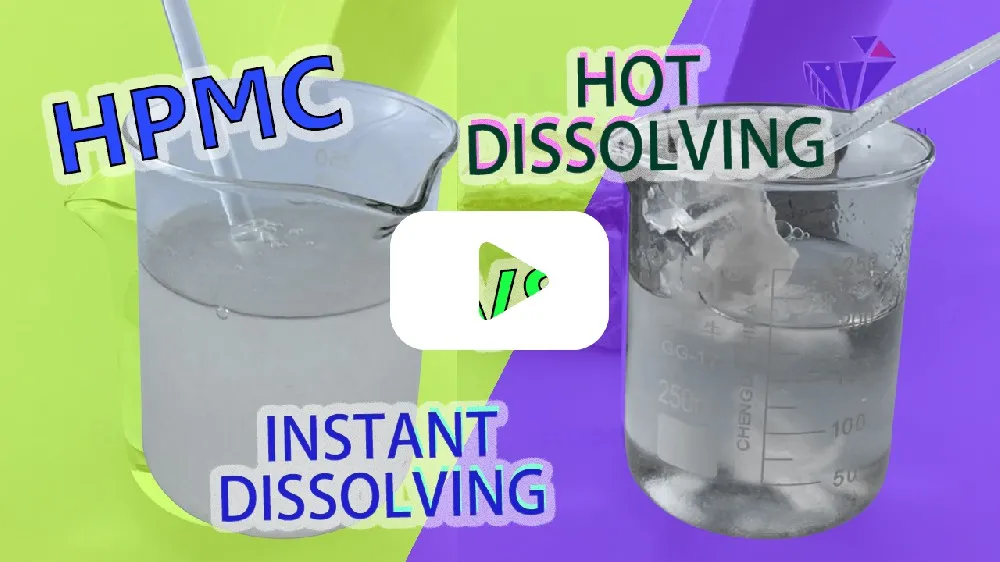

Hydroxyethylcellulose is an effective film-forming agent, adhesive, thickener, stabilizer and dispersant in shampoos, hair sprays, neutralizers, conditioners and cosmetics; in laundry detergents it is a foulant redeposition agent. Hydroxyethyl cellulose dissolves quickly at high temperatures, which can speed up the production process and improve production efficiency. The distinctive feature of the detergent is that it contains hydroxyethyl cellulose and its advantage is that it can improve the smoothness and mercerization of the fabric.

-

Moreover, increased focus on sustainability is shaping the market. Manufacturers are increasingly looking for eco-friendly ways to produce hydroxyethylcellulose, which may lead to shifts in pricing structures as investments in sustainable production techniques rise.

-

4. Personal Care

-

The Role of Methyl Hydroxyethyl Cellulose in Modern Industries

-

1. Raw Material Costs The primary determinant of HPMC prices is the cost of raw materials. HPMC is synthesized from cellulose, which is derived from wood pulp, cotton linters, or other natural sources. Fluctuations in the prices of these raw materials due to environmental conditions, labor costs, or geopolitical factors can directly influence HPMC pricing.

-

Applications of Hydroxyethyl Cellulose

-

HPMC is increasingly being used in the food industry as a food additive. It serves multiple purposes, such as improving texture, viscosity, and stability of food products. Common applications include sauces, dressings, dairy products, and baked goods. In gluten-free baking, HPMC acts as a substitute for gluten, providing the elasticity and structure that is typically lacking in gluten-free products. Furthermore, its emulsifying properties help maintain the quality of processed foods, extending shelf life and enhancing flavor profiles.

-

If you’re looking to purchase Cellosize in bulk, you might want to consider going through distributors or wholesalers. These companies often have direct relationships with manufacturers and can offer competitive pricing on larger orders. In addition to cost savings, buying in bulk can ensure a consistent supply for ongoing projects. Distributors often provide technical advice and customer support which can be invaluable, especially if you are unfamiliar with specific applications of hydroxyethyl cellulose.

- The viscosity of HEC solutions also varies with temperature, with higher temperatures typically leading to lower viscosities. This is because higher temperatures disrupt the interactions between polymer chains, reducing the overall viscosity of the solution. However, the exact relationship between temperature and viscosity can vary depending on the specific characteristics of the HEC polymer.

One of the key features of HPMC is its water-solubility, which makes it an ideal ingredient in many applications. It is commonly used as a thickener, binder, film-former, and stabilizer in a wide range of products, including pharmaceuticals, personal care products, construction materials, and food.

Understanding China HPMC Powder An Essential Ingredient in Modern Industries

Applications of Hydroxyethyl Cellulose Viscosity

4. Enhanced Adhesion HPMC promotes better adhesion of the gypsum plaster to various substrates, including concrete, brick, and block surfaces. This improved bonding ensures that the plaster remains intact over time, reducing the likelihood of delamination or peeling.

hydroxyethyl cellulose where to buy.

The construction industry has also benefited from the unique properties of HPMC. It is commonly used in the formulation of cement-based dry-mix products, such as tile adhesives and joint compounds. HPMC improves workability, water retention, and adhesion of these materials, making application easier while ensuring durability and performance. Moreover, its water-retaining properties are critical, as they allow for better curing of cement, which ultimately enhances the strength of the final structure.

hpmc hydroxypropyl methylcellulose

China has emerged as a key player in the global market for HPMC, with a robust manufacturing infrastructure and expertise. Chinese manufacturers produce a wide range of HPMC grades suitable for various applications, ensuring that client needs are met with precision. The commitment to quality control and sustainability is paramount, with many manufacturers adhering to international standards to compete on the global stage.

4. Construction HEC is employed in construction materials, particularly in cement-based products. Its water retention properties enhance workability and improve the bonding of materials. Additionally, HEC helps prevent cracking in mortars and plasters, making it a vital component in modern construction practices.

hpmc grades. These grades provide excellent sag resistance and can enhance the durability and performance of the final product. They are also used as thickening agents in food products and pharmaceutical formulations.

hpmc for gypsum. This means that it forms a thin, protective layer on the surface of the material, which helps to improve its water resistance, adhesion, and overall performance. This is particularly important in applications where the gypsum product will be exposed to moisture or weathering, such as in outdoor construction or wet environments.

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer derived from cellulose, extensively used in various industries, including pharmaceuticals, food, and construction. One crucial characteristic that defines the utility of HPMC is its density, which plays a significant role in determining its performance in different applications. Understanding HPMC density is essential for manufacturers and researchers who aim to optimize formulations and processes.

Conclusion

What Is HPMC?

What is HPMC?

Future Opportunities

HPMC for Wall Putty Enhancing Performance and Application

Finally, in the cosmetic and personal care sector, various grades of HPMC are utilized for their thickening, emulsifying, and stabilizing properties in lotions, creams, and gels. The ability to form a transparent film makes HPMC an attractive ingredient in many formulations, ensuring effective delivery of active ingredients while maintaining product stability.

RDPs find numerous applications across the construction sector

. One of the most common uses is in tile adhesives, where the addition of redispersible polymer powder improves bonding strength and flexibility. This is particularly important for applications involving different substrates or areas exposed to temperature fluctuations and movement.